Repeatable, reliable and scalable additive manufacturing solutions for passive radio frequency (RF) system designers

Our global Application Innovation Group (AIG) reduces risk and creates a faster ROI for our customers by developing qualified, transferrable, and scalable production processes to companies of all sizes – with a business model designed to let you keep your IP and grow capability in your preferred supply chain.

Driven by system requirements we work with customers to identify the best material and processes for each design. Typical solutions include Ti Gr 23 with optional silver coating, AlSi10Mg, 6061-RAM2, Scalmalloy, or Cu.

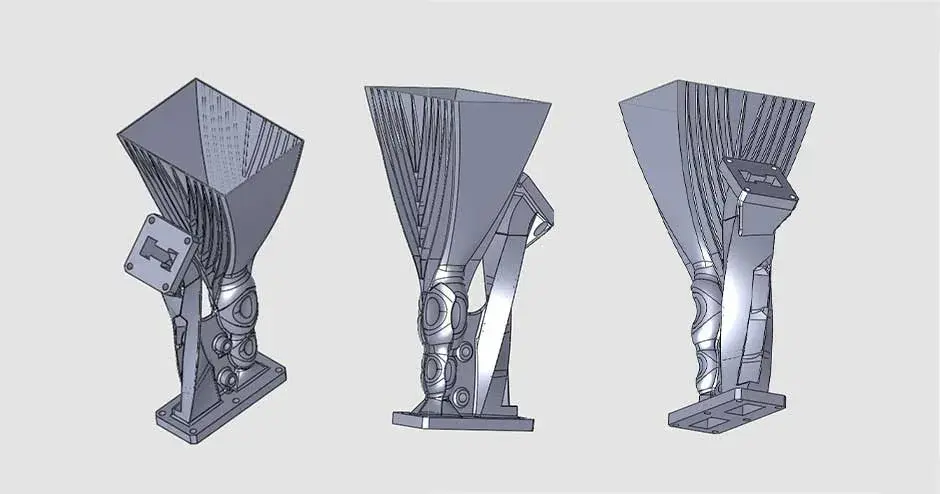

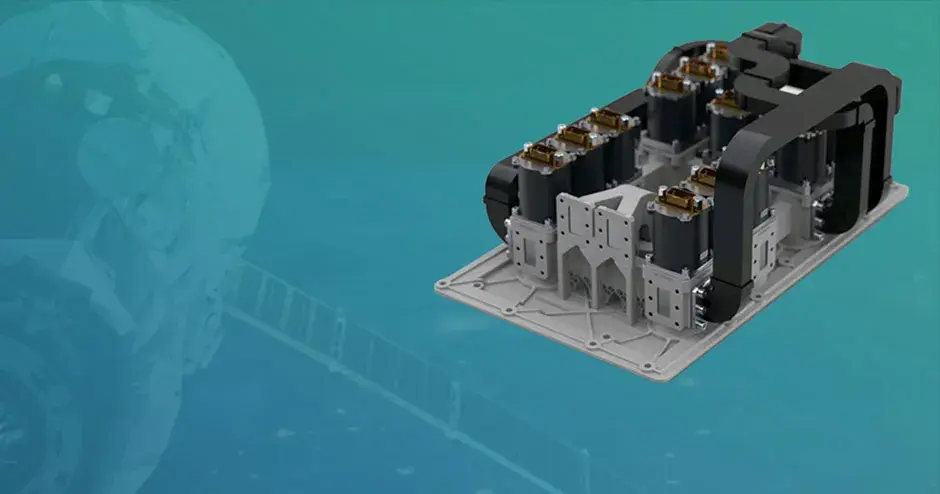

Simplify complex RF hardware to reduce part count and eliminate costly assembly, test, and integration steps. Direct metal printing (DMP) helps our customers impact system level performance by reducing assemblies into single monolithic structures.

Increasing the capacity for multiple beams within a single satellite is a major industry trend. While reduced weight drives major improvements, volume is also mission critical. Better packaging efficiencies allow more channels for more services within the limited satellite design volume.

D. Gonzalez-Ovejero, N. Chahat, R. Sauleau, G. Chattopadhyay, S. Maci and M. Ettorre, "Additive Manufactured Metal-Only Modulated Metasurface Antennas," IEEE Transactions on Antennas and Propagation, vol. 66, no. 11, pp. 6106-6114, Nov. 2018

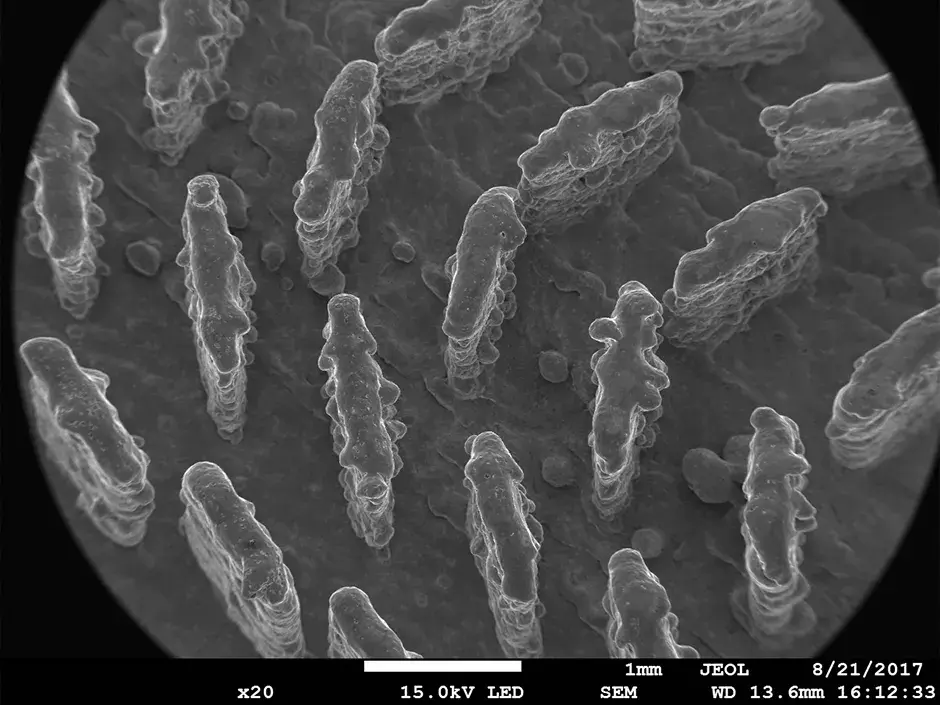

Machined surfaces have sharp peaks and troughs, while 3D printed surfaces are made of spheroids melted together for a smooth surface topology. Testing has demonstrated that additively manufactured RF components can perform as well or better than machined surfaces even with higher Ra values. Additive manufacturing enables the ability to shape a part for more effective signal filtering with an optimized surface topology.

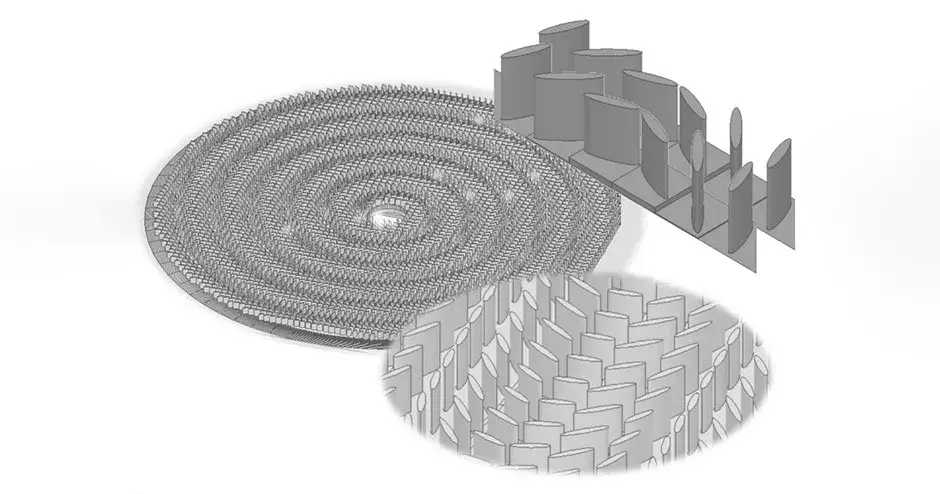

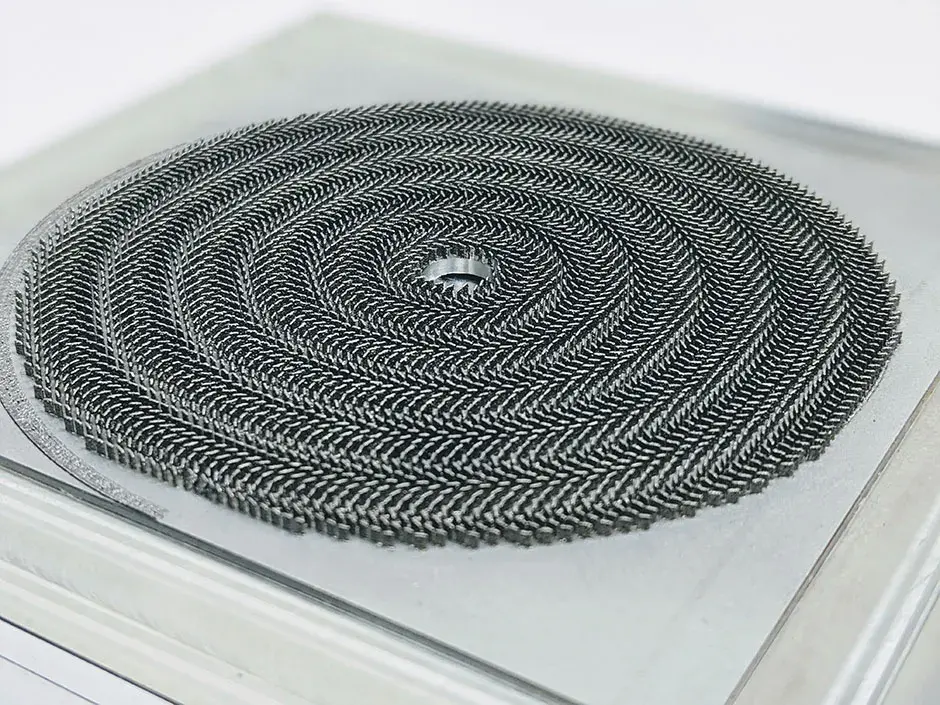

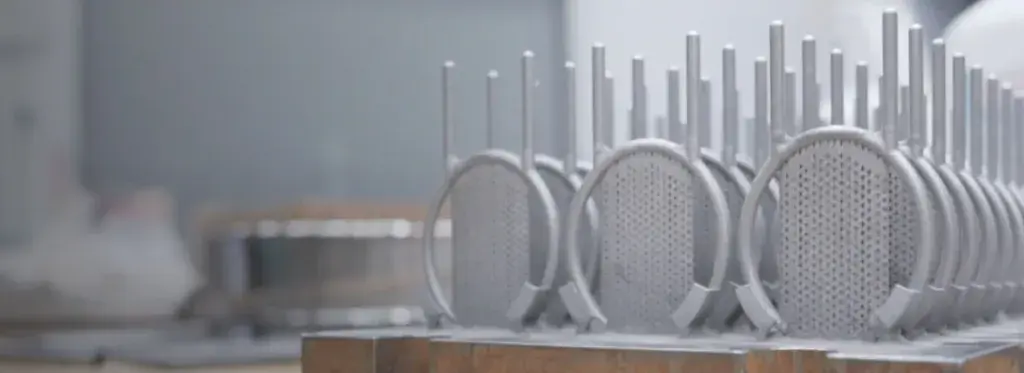

In collaboration with NASA’s Jet Propulsion Laboratory and the Univ Rennes, CNRS, IETR - UMR 6164, 3D Systems produced several thousand elements of this MTS antenna on a single base plate. Low profile and low mass make this an ideal Ka band antenna type for SmallSats and CubeSats.

Reference: D. González‐Ovejero, O. Yurduseven, G. Chattopadhyay and N. Chahat, “Metasurface Antennas: Flat Antennas for Small Satellites,” in CubeSat Antenna Design , IEEE, 2021, pp.255-313.

Macro view of 10 cm diameter antenna face.

Integral rectangular waveguides machined into reverse side of base plate

Zoom to central region in 10cm diameter antenna face

20x SEM image of individual elements

3D Systems has in-house aerospace industry experts across all major aspects of aerospace parts manufacturing, from engineering and design to certification and production. Our experts work with you to optimize your efforts in manufacturing aerospace components for commercial, business, military, aviation, and space applications.

Based on more than a decade of leading-edge manufacturing within highly regulated environments such as healthcare, aerospace, and high tech, we provide you with unique insights, assist in the certification process, and enable a streamlined pathway to full-scale manufacturing using our innovative technology.

Our two AS/EN9100 production facilities allow for parallel paths to application development and on-site customer process development. This streamlines the implementation of additive manufacturing and results in an ROI of up to 60%.

Explore how major OEMs, suppliers, and research institutions have designed and proven lightweight structure and passive radio frequency (RF) components for ground and space with additive manufacturing (AM).

3D Systems’ Application Innovation Group assisted with process development, bridge production, technology transfer of additively manufactured radio frequency (RF) patch antennas for small satellite applications.

3D Systems’ AIG designed an end-to-end AM solution – comprising its DMP Factory 500, materials, software, and applications expertise – to deliver fully-qualified processes and components required for the large antenna array.

Our company has a strong partnership with 3D Systems and has relied on its team of application engineers to help us bring our most advanced designs to life. Everything from the quality of the parts produced using their printers, through to parts qualification, quality management, and overall project management have helped Airbus Defence and Space maintain its position as an industry leader.—Stephen Phipps, OneSat antenna program manager, Airbus Defence and Space

Robust, high quality metal AM with integrated powder management

Good mechanical properties and good thermal conductivity

All-in-One Integrated Software for Industrial Additive Manufacturing